Ceylon Graphite’s Anode Graphite in Full Cell Lithium Ion Batteries Outperforms Leading Commercial Synthetic Graphite

4 min read

In a significant breakthrough in the performance of its vein graphite anode material in full cells for the lithium-ion (“Li-ion”) battery market, Ceylon Graphite Corp. (Ceylon Graphite)today announced that its vein graphite anode material far exceeded comparable anodes made with industry-standard commercial synthetic graphite

The tests were conducted at a leading global, independent facility, University College London (UCL).

“Ceylon’s vein graphite anode material far exceeded comparable anodes made with industry-standard commercial synthetic graphite. This is the first time in battery research history that commercial spherodized vein graphite materials were tested in a lithium ion battery in a full cell,” Ceylon Graphite announced in a media release.

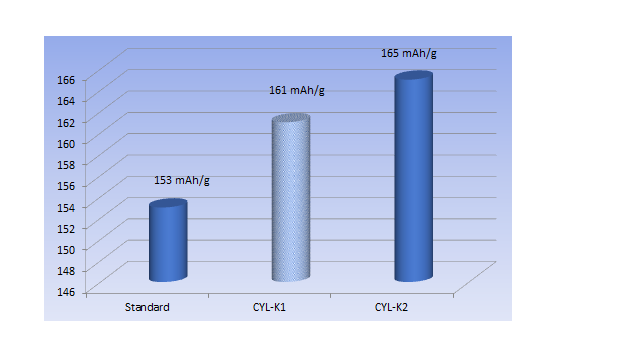

Results came in at 161 and 165 mAh/g for specific discharge capacity (SDC) for our vein graphite materials, which is beyond what is expected for the best current commercially used synthetic graphite with a specific capacity of 153 mAh/g.

The outstanding performance of Ceylon’s vein graphite material against the current commercially used synthetic graphite is due to the high crystallinity of Sri Lankan vein graphite and the near- perfect morphology of the coated spherodized anode material (shown in the SEM image) produced by proprietary processing and spherodizing technology of Ceylon Graphite Technologies. The initial results prove the suitability of our material for lithium ion battery anodes for either stand-alone or possible blending with synthetic graphite.

“These results are a highly significant development for Ceylon. The unique characteristics of our Sri Lankan vein graphite combined with our proprietary processing technologies produces a Li-ion battery with significantly higher power and energy as tested by UCL. Based on the results,Ceylon’s graphite will set a new industry standard. In addition, we believe that the energy consumption of the end to end process of producing battery grade anode material from vein graphite is the lowest, relative to synthetic and flake graphite, because of the fact that vein graphite from Sri Lanka does not require primary processing, due to the high in situ grade above 90%Cg,” Ceylon Graphite CEO, Don Baxter stated.

The ongoing testing and optimization of Ceylon’s battery materials and Ceylon’s unique position in the market create optionality for scale-up development, commercial partnerships and sales of advanced materials. Ceylon’s significant resource positions and our energy products division (Ceylon Graphite Technologies(UK)) will allow The Company to evolve into a stand-alone battery technology company, with exclusive access to a lower cost and, unique, high performance battery grade graphite, sourced from our wholly owned deposits in Sri Lanka.

Extended cycling exhibited reversible charge/discharge behaviour with less than 10% overall capacity loss over 50 cycles. The C/5 stable cycling (25 to 50) gives an average reversible capacity of 155mAh/g for the best performing vein graphite material, compared to 139mAh/g for standard synthetic graphite. The batteries were tested in a full cell system at a rate of C/5, meaning 5 hours to charge and 5 hours to discharge, hence completing about 2+ full cycles per day, from 25 to 50 cycles. The Chart below illustrates the cycling of Ceylon’s anode material versus the standard synthetic:

The outstanding performance of Ceylon’s vein graphite material against the current commercially used synthetic graphite is due to the high crystallinity of Sri Lankan vein graphite and the near- perfect morphology of the coated spherodized anode material (shown in the SEM image) produced by proprietary processing and spherodizing technology of Ceylon Graphite Technologies. The initial results prove the suitability of our material for lithium ion battery anodes for either stand alone or possible blending with synthetic graphite.

Dr Dan Brett, Professor of Electrochemical Engineering At UCL stated: “These are very promising results and I’m excited at the prospect of Sri Lanka using this wonderful natural resource to play a major role in realising the ‘age of electrochemical power’ and achieving Net Zero.” Dr. Brett is Professor of Electrochemical Engineering at UCL, where he is a director of the Electrochemical Innovation Lab (EIL) and Advanced Propulsion Lab (APL). He is an academic founder of the Faraday Institution and member of the Expert Panel.

Ceylon CEO, Don Baxter stated, “ We had very good results from our initial coin cell battery tests, but was excited to see my expectations for full cell batteries being far exceeded by our vein graphite. These results are a highly significant development for Ceylon. The unique characteristics of our Sri Lankan vein graphite combined with our proprietary processing technologies produces a Li-ion battery with significantly higher power and energy as tested by UCL. Based on the results,Ceylon’s graphite will set a new industry standard. In addition, we believe that the energy consumption of the end to end process of producing battery grade anode material from vein graphite is the lowest, relative to synthetic and flake graphite, because of the fact that vein graphite from Sri Lanka does not require primary processing, due to the high in situ grade above 90%Cg.”

The ongoing testing and optimization of Ceylon’s battery materials and Ceylon’s unique position in the market create optionality for scale-up development, commercial partnerships and sales of advanced materials. Ceylon’s significant resource positions and our energy products division (Ceylon Graphite Technologies(UK)) will allow The Company to evolve into a stand-alone battery technology company, with exclusive access to a lower cost and, unique, high performance battery grade graphite, sourced from our wholly owned deposits in Sri Lanka.